Analysis of Crane Grabs Based on JB/T 13481-2018

Jan 20,2025

A crane grab is a specialized tool for handling bulk materials. The grab consists of two or more closable shell plates forming a containment space. During loading, the shell plates close within the material pile, capturing material in the containment space; during unloading, the shell plates open while suspended above the pile, allowing material to fall.

I. Standard Scope and Terminology

This standard applies to crane grabs used in general environments. It does not apply to:

● Environments with flammable/explosive materials

● Combustible gases and dust

● Corrosive atmospheres

● Nuclear radiation environments

● Toxic gas environments

Key definitions:

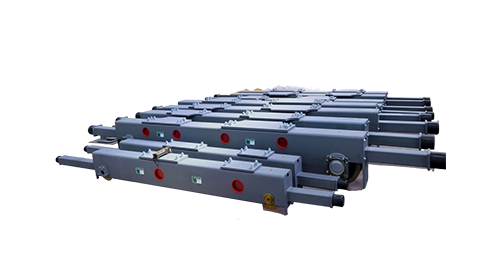

● Mechanical drive grab: A mechanical grab controlled by wire ropes for shell opening/closing

● Electric grab: A grab with electric drive units mounted on it, controlling shell movements via wire ropes

● Electric-hydraulic grab: A grab with electric-driven hydraulic system controlling shell movements

● Rated capacity: Sum of maximum material weight and grab self-weight

● Theoretical volume: Design volume

Note: For double-shell grabs, the theoretical volume is the space enclosed by side plates, bottom plates, and material pile angle when closed. For multi-shell grabs, it's the volume enclosed by shell tips, shell plates, and frame bottom when closed. Special material volumes can be agreed upon by both parties.

Grab weight: Maximum mass of the unloaded grab (including working medium for electric-hydraulic grabs).

II. Grab Types and Operating Parameters

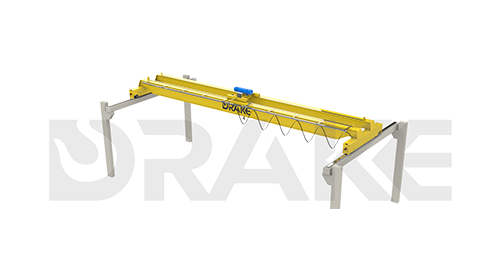

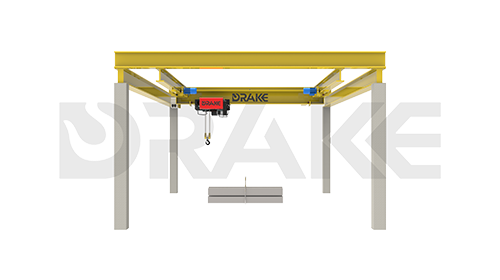

Grabs are classified by control method, shell structure, and material bulk density (refer to Figures 1-9).

Basic parameters include:

● Rated capacity

● Material bulk density

● Material pile angle

● Material particle size

● Theoretical volume

● Wire rope diameter

● Pulley diameter

● Motor power

● Self-weight

Notes:

1.Material pile angle is the maximum angle between the material's natural pile surface and horizontal plane.

2.Material particle size classifications:

● Macro particles: 1-10mm (stones, metal blocks, coke)

● Medium particles: 0.1-1mm (herbs, plastic granules, coal powder)

● Micro particles: 0.01-0.1mm (medicine powder, cement powder)

● Ultra-fine particles: 0.001-0.01mm (nano materials, polymers)

III. Technical Requirements

1.Operating Environment and Performance

● Temperature range: -20℃ to +40℃ (-10℃ to +40℃ for electric-hydraulic grabs)

● Filling rate: ≥90%

2.Materials and Manufacturing Quality

● Structure material: Not lower than Q355B

● Main load-bearing pins: Not lower than Grade 45 steel

● Shell edge hardness: ≥300HBW

● Shell tips: ≥450HBW or wear-resistant alloy castings

● Double-shell closure gaps: ≤2mm

● Shell edge misalignment: ≤4mm

● Underwater grab gaps: ≤10mm

● Multi-shell tip height difference: ≤±15mm

3.Hydraulic System and Safety Requirements

● Working pressure: ≤85% of rated pump pressure

● Motor protection: ≥IP54

● Insulation class: ≥Class F

● Pulley guard clearance: ≤20% of rope diameter

● Pulley/rope diameter ratio: ≥18

IV. Marking, Packaging, Transport and Storage

● Nameplate requirements: Manufacturer, model, parameters, serial number, date

● Shipping documents: Packing list, certificate, manual

● Transport protection against self-operation

● Storage: Protect from rain and water immersion