Analysis of Seven Categories of Bridge Cranes: Terminology and Types

Feb 24,2025

Bridge crane is one of the ten major categories of cranes, defined as: A crane whose bridge girder is supported on rails or directly on bearing surfaces through traveling mechanisms. According to GB/T 6974.5-2023, we study the "terminology and types" of seven categories of bridge cranes, including general bridge cranes, metallurgical bridge cranes, explosion-proof bridge cranes, electric single-girder cranes, electric hoist bridge cranes, insulated bridge cranes, and nuclear power plant circular cranes.

I. General Bridge Cranes

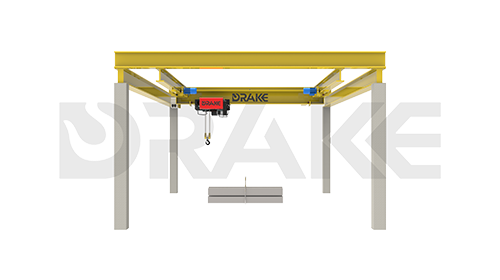

- General Bridge Crane: A bridge crane for general purposes in normal environments, with lifting devices such as hooks, grabs, electromagnetic discs, or combinations thereof.

- Stacking Bridge Crane: Usually employs forks as lifting devices, guided by columns, used for stacking or retrieving packaged items in warehouses or workshops.

- Automated Storage/Retrieval System (ASRS) Crane: Operates along tracks in automated warehouse aisles, performing storage and retrieval operations.

II. Metallurgical Bridge Cranes

- Metallurgical Bridge Crane: Designed for special requirements in metal smelting, casting, rolling, and heat treatment, directly used in production processes.

- Charging Crane: A metallurgical bridge crane using hoppers or baskets for charging converters or electric furnaces.

- Forging Crane: A metallurgical crane with shock absorption devices for lifting and turning forgings.

- Slab Transfer Crane: A metallurgical crane using slab tongs or electromagnetic plates for handling and stacking slabs.

- Casting Crane: A metallurgical crane for handling molten metal.

- Quenching Crane: A metallurgical crane used in vertical pit heat treatment processes, featuring rapid descent and emergency brake release for hot, large, or elongated workpieces.

- Rake Crane: A metallurgical bridge crane with rakes (or additional electromagnetic plates) for handling and stacking bar billets in steel plant continuous casting and rolling processes.

- Soaking Pit Tong Crane: A metallurgical bridge crane using tongs for charging soaking pits.

III. Explosion-Proof Bridge Cranes

- Explosion-Proof Bridge Crane: Bridge cranes with explosion-proof capabilities for use in explosive gas or dust environments (JB/T 5897-2014).

- Clean Room Bridge Crane: Bridge cranes for use in clean environments with specific cleanliness requirements (JB/T 14201-2022).

IV. Electric Single-Girder Cranes

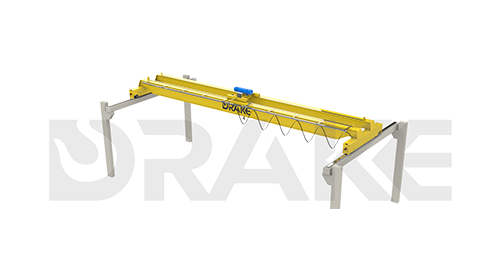

- Electric Single-Girder Crane: Single main girder bridge crane using electric hoists in general environments.

- Electric Suspended Crane: Bridge crane with the girder suspended below the track, using electric hoists in general environments.

- Flexible Modular Suspended Crane: Bridge crane using electric hoists running under modular profile tracks in general environments.

V. Electric Hoist Bridge Cranes

- Electric Hoist Bridge Crane: Double main girder bridge crane using electric hoists in general environments.

VI. Insulated Bridge Cranes

- Insulated Bridge Crane: Bridge crane with insulation capabilities for non-ferrous metal electrolysis workshops.

- PTM (Pot Tending Machine): Bridge crane with tool trolleys and aluminum extraction trolleys for pre-melted anode aluminum electrolysis.

- FTA (Fume Treatment Anode crane): Bridge crane with vacuum material handling for anode baking furnaces.

- ASC (Anode Stacking Crane): Bridge crane with carbon block grippers for handling and stacking anode blocks.

- Electrolytic Copper Crane: Bridge crane with rigid-guided special lifting devices for electrolytic copper production.

VII. Nuclear Power Plant Circular Cranes

- Nuclear Power Plant Circular Crane: Bridge crane operating on circular tracks in nuclear power plant reactor buildings.

- Spent Fuel Container Crane: Bridge crane for handling spent fuel transport containers.

- Spent Fuel Pool Crane: Bridge crane for loading/unloading new and spent fuel in fuel storage pools.

- Fuel Building Auxiliary Crane: Bridge crane sharing tracks with spent fuel pool crane for handling new fuel and containers.