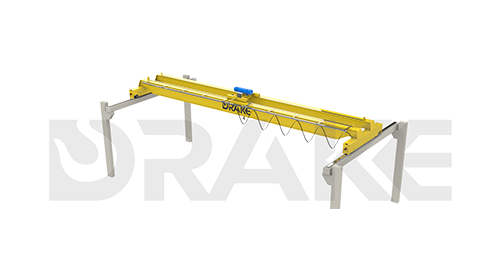

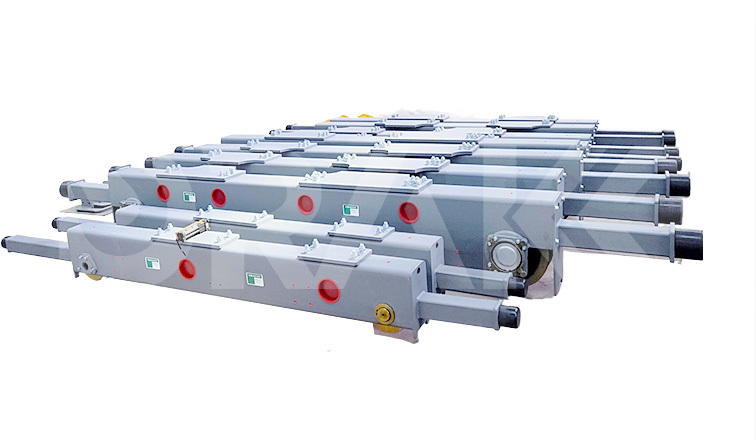

FEM/DIN Standards Double Girder Overhead Crane

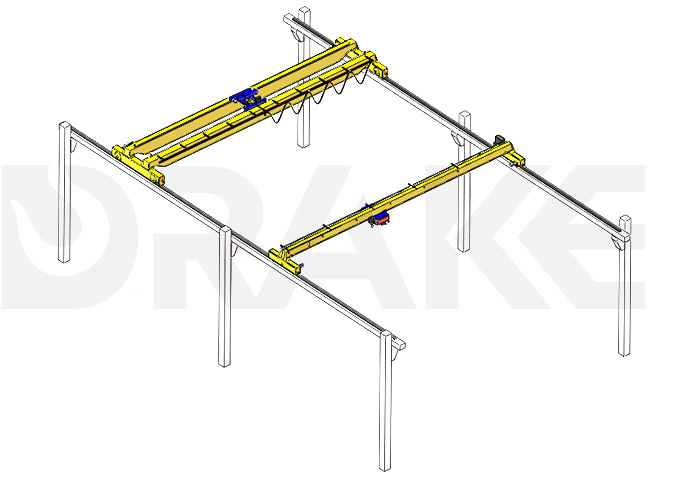

The FEM/DIN Standards double girder overhead crane is extensively utilized in steel mills, foundries, large machine workshops, chemical facilities, and storage warehouses to provide more efficient logistic solutions, especially suitable for locations requiring precise positioning. Furthermore, the FEM/DIN double girder overhead crane adopts a lightweight and modular design, resulting in a 20%-30% reduction in overall height and weight compared to traditional cranes of the same lifting capacity.

5~50tons

Capacity

6~24m

Lift height

35m

Span

M3~M6

Working Class

Low cost

The lightweight and modular design results in the overall weight and height of the crane being 20%-30% lower than traditional cranes of similar capacity, and the integrated transmission mechanism improves operational efficiency, resulting in an energy saving of approximately 26% compared to traditional cranes for the Drake crane.

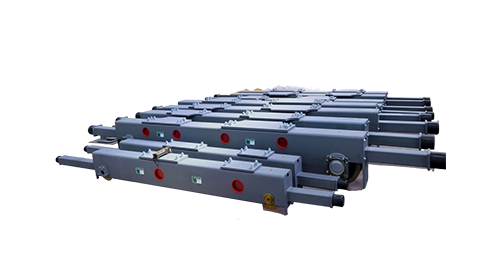

High manufacturing standards

The steel materials undergo pre-sanding treatment to eliminate surface stress, while CNC cutting machines are utilized to ensure smooth curves and minimize errors. Gantry automatic arc welding is employed for high-efficiency welding without the presence of bubbles.

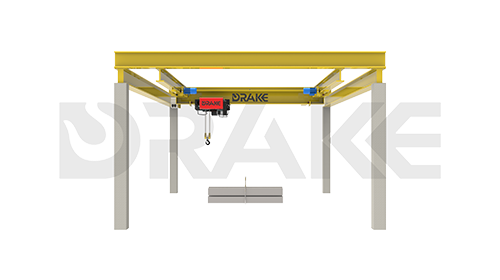

Enhanced safety measures

The entire machine is equipped with overload and lifting limiters to prevent operators from lifting excessive loads and the risk of over-topping. The main electrical components are sourced from internationally renowned brands such as Siemens and Schneider etc. The wheel is forged from 65Mn alloy steel, featuring characteristics such as wear resistance, fatigue resistance, and long service life.

The entire machine is equipped with overload and lifting limiters to prevent operators from lifting excessive loads and the risk of over-topping. The main electrical components are sourced from internationally renowned brands such as Siemens and Schneider etc. The wheel is forged from 65Mn alloy steel, featuring characteristics such as wear resistance, fatigue resistance, and long service life.

| Technical Specifications | |||||||

| Lifting Capacity | t | 5 | 10 | 16 | 20 | 32 | 50 |

| Span | 10.5m~31.5m,or customizable | ||||||

| Lifting Height | M | 6m~24m,or customizable | |||||

| Lifting Speed | m/min | 0.8/5 | 0.8/5 | 0.66/4 | 0.53/3.4 | 0.8/3.3 | 0.53/3.2 |

| Trolley Travelling Speed | m/min | 2~20 | 2~20 | 2~20 | 2~20 | 2~20 | 2~20 |

| Crane Travelling Speed | m/min | 3~30 | 3~30 | 3~30 | 3~30 | 3~30 | 3~30 |

| Work Duty | A5 | ||||||

| Power Supply | 380V 50Hz,or customizable | ||||||

Keywords:

FEM/DIN Standards Double Girder Overhead Crane

FEM/DIN Standards Double Girder Overhead Crane

Flexible customization services: Drake has dozens of experienced crane design experts and teams with extensive manufacturing experience. Specializing in providing customized lifting solutions that meet our customers' specific requirements. Our modular design ensures a robust structure and standardized production, to reduce unnecessary costs. The main components of Drake standard cranes are primarily sourced from world-renowned and top domestic brands, including ABB/SEW/Siemens/Jiamusi/Drake motors, SEW/DongTai gearboxes, and FAG/SKF/NSK/LYC/HRB bearings.

Get A Quote

Leave your contact information and get a free product quote

PROJECT CASES

Drake( Henan) Intelligent Equipment Co., Ltd. Is a modern enterprise with independent import and export management rights integrating crane R&D, design, production, installation and service.

SOLUTION

Shipbuilding, machinery, furniture, automotive, chemical, construction

Can be widely used in factories, mines, workshops, production lines, assembly lines and machine tools up

For warehouses, logistics, production plants, harbor terminals, etc.

Double girder overhead crane are widely used in workshops, warehouses and yards of petroleum and petro...