Crane Safety Hazard Inspection (With References): Focus on These 15 Items

Mar 10,2025

1. Regular Inspection

Inspection Item: Check whether the crane is inspected regularly as required.

Reference:

- TSG51-2023 Crane Safety Technical Code, Article 6.4.2

- Inspection Frequency:

- Tower cranes, lifts, mobile cranes, and cable cranes: once a year;

- Overhead cranes, gantry cranes, portal cranes, derrick cranes, and mechanical parking equipment: once every 2 years.

- Inspection Frequency:

2. Certified Operators

Inspection Item: Verify whether the operators hold the appropriate special equipment operation certificates.

Reference:

- TSG Z6001-2019 Rules for Special Equipment Operators' Assessment, Appendix J

- Operators of overhead cranes, tower cranes, etc., must obtain a Special Equipment Operation Certificate.

- Ground operators and remote control operators should be trained and managed in accordance with the rules.

3. Wire Rope Splicing Length

Inspection Item: Check whether the wire rope splicing length meets the following requirements:

- General Machinery: Splicing length should not be less than 15 times the diameter of the wire rope and no less than 300 mm;

- Construction Machinery: Splicing length should not be less than 20 times the diameter of the wire rope and no less than 300 mm.

Reference:

- GB6067.1-2010 Crane Safety Code, Article 4.2.1

- JGJ33-2012 Technical Code for Safe Use of Construction Machinery, Article 4.1.26

4. Wire Rope Clips

Inspection Item: Check whether the number of wire rope clips is at least 3, the spacing is 6-7 times the diameter of the wire rope, and the length from the last clip to the rope end is greater than 140 mm.

Reference:

- GB6067.1-2010 Crane Safety Code, Article 4.2.1.5

- JGJ33-2012 Technical Code for Safe Use of Construction Machinery, Article 4.1.26

5. Wire Rope Scrap Standards

Inspection Item: Check whether the wire rope has broken strands, burrs, rust, bends, or other conditions that meet the scrapping criteria.

Reference:

- GB/T5972-2009 Maintenance, Installation, Inspection, and Scrap Standards for Crane Wire Ropes, Article 3.5

6. Anti-Derailment Measures

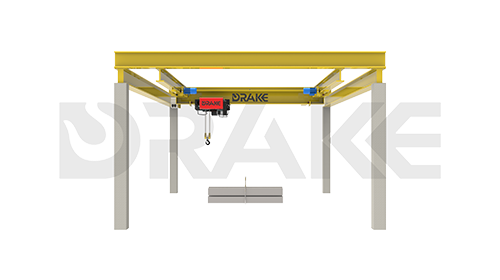

Inspection Item: Check whether single-girder cranes have anti-derailment measures for wire ropes.

Reference:

- GB6067.1-2010 Crane Safety Code, Article 4.2.5.1

7. Hoist Height Limiter

Inspection Item: Check whether the crane is equipped with a hoist height limiter.

Reference:

- GB6067.1-2010 Crane Safety Code, Article 9.2.1

8. Anti-Unhooking Device

Inspection Item: Check whether the lifting hook is equipped with an anti-unhooking device.

Reference:

- GB6067.1-2010 Crane Safety Code, Article 4.2.2.3

9. Overload Limiter

Inspection Item: Check whether cranes with a capacity of 1 ton or more are equipped with an overload limiter.

Reference:

- GB6067.1-2010 Crane Safety Code, Article 9.3.1

10. Load Capacity Label

Inspection Item: Check whether the crane has a clear and permanently fixed load capacity label.

Reference:

- GB6067.1-2010 Crane Safety Code, Article 10.1.1

11. Warning Signs

Inspection Item: Check whether warning signs such as "No Standing Under Load" and "Beware of Suspended Loads" are posted at the work site.

Reference:

- Work Safety Law of the People's Republic of China, Article 35

12. Buffer Device

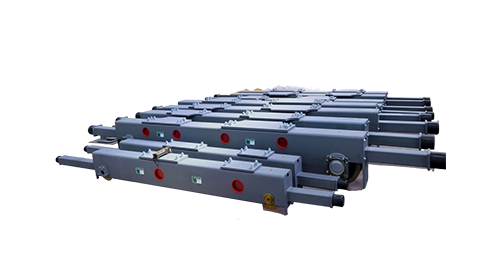

Inspection Item: Check whether the crane's trolley or runway mechanism is equipped with a buffer device.

Reference:

- GB6067.1-2010 Crane Safety Code, Article 9.2.10

13. Hook Wear

Inspection Item: Check whether the hook wear exceeds 5% of its original size, meeting the scrapping criteria.

Reference:

- GB/T10051.3-2010 Inspection for Forged Hooks, Article 3.2.3

14. Anti-Collision Device

Inspection Item: Check whether multiple cranes operating on the same track are equipped with anti-collision devices.

Reference:

- GB6067.1-2010 Crane Safety Code, Article 9.2.9

15. Emergency Stop Device

Inspection Item: Check whether the crane is equipped with an emergency stop device that operates reliably.

Reference:

- GB6067.1-2010 Crane Safety Code, Article 9.2.4

Conclusion

The safety management of cranes is a critical aspect of ensuring safe production. Regular inspections, strict adherence to standards, and proper operation can effectively reduce safety risks and ensure a safe working environment.