Analysis of Wire Rope Electric Hoist Types, Basic Parameters, and Technical Conditions

Feb 17,2025

Electric hoists are small lifting equipment with advantages such as compact structure, light weight, small volume, strong component universality, and easy operation. They are mainly used for various lifting, pulling, loading and unloading operations, oil tank overturning welding, and installation and movement of various large and medium-sized concrete, steel structures, and mechanical equipment. Based on JB/T 9008.1-2014, this analyzes the terminology and definitions, types and basic parameters, technical conditions, inspection rules, markings, packaging, transportation, and storage of "Wire Rope Electric Hoists."

I. Standard Scope and Terminology Applies to wire rope electric hoists (hereinafter referred to as "electric hoists") used in general working environments or for lifting molten metals; not applicable in environments with explosive gases, combustible dust, or corrosive gases; not applicable in nuclear radiation or toxic gas environments. Electric hoist: A lifting device combining electric motor, reducer, brake, etc., into one unit, finally operating through a drum winding/unwinding lifting rope or chain wheel handling lifting chain to drive the lifting device up and down. Hook safety distance: The minimum distance between the hook assembly at its upper limit position when the drum stops rotating and possible obstacles.

II. Types and Basic Parameters Electric hoists are classified according to their traveling mechanism:

- Fixed electric hoists

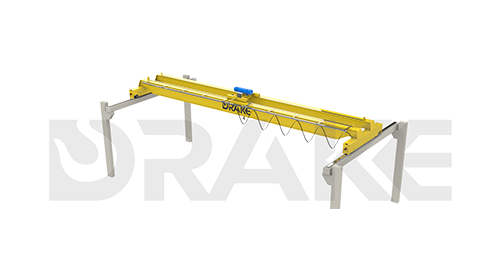

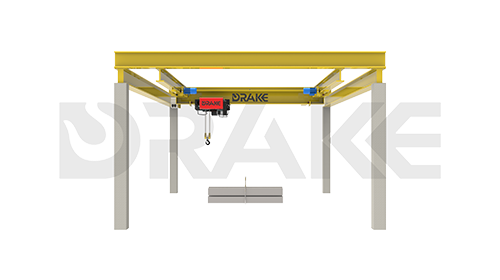

- Single-beam trolley electric hoists

- Double-beam trolley electric hoists Note: Fixed electric hoists are divided into supported and suspended types. Supported types are further divided by foot position into top-fixed, bottom-fixed, left-fixed, and right-fixed. Single-beam trolley hoists are divided into standard and low headroom types. Both single-beam and double-beam trolley types have traveling mechanisms. The lifting duty classifications are divided into eight levels from M1 to M8.

III. Technical Requirements

- Working Environment

- Single or three-phase AC 110V~660V, 50Hz~60Hz, motor voltage fluctuation ≤10% of rated voltage

- General working temperature -20℃~40℃, molten metal lifting -10℃~60℃

- Humidity ≤50% at 40℃

- Altitude ≤1000m

- Performance Requirements

- Hook should rotate freely 360° in horizontal plane

- Wire rope center line deviation ≤3.5° from spiral groove centerline

- Travel speed deviation ±15% of nominal value (slow speed not assessed)

- Lifting speed deviation ±10% of nominal value

- Lowering speed deviation -10%~25% (slow speed not assessed)

- Brake slip ≤v/100 under rated load (v = stable 1min lifting distance)

- Hook safety distance ≥100mm

IV. Safety and Hygiene

- Safety Protection Devices

- Upper and lower limit switches

- Double fiber protection for molten metal lifting

- Hook load capacity marking and locking device

- Load limiter for ≥1t capacity

- Brake safety factor ≥1.5 for M5 and below, ≥1.75 for above M5

- Safety Measures

- Minimum 2 safety turns on drum

- Insulation resistance ≥1Ω

- Ground connection resistance ≤0.1Ω

- Noise level ≤85dB

- Asbestos-free brake friction materials

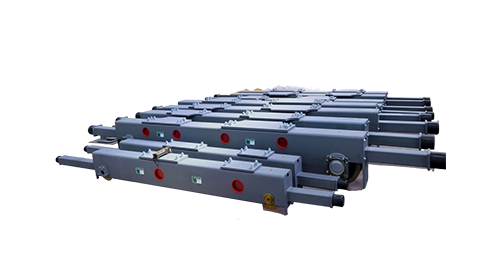

V. Main Components

- Wire rope complying with GB/T 20118

- Minimum tensile strength 1570MPa

- Special requirements for molten metal lifting

- Emergency stop switch (red, non-auto-reset)

- Ground connection ≥M6

- Safety voltage ≤50V for pendant control

VI. Marking, Packaging, Transportation, and Storage

- Nameplate according to GB/T 13306

- Documentation including manual, certificate, packing list

- Storage with rust prevention, moisture protection, ventilation