The Inner Workings of Overhead Cranes: A Comprehensive Guide

Jul 10,2025

Unveiling Overhead Cranes: The Backbone of Heavy Lifting

Overhead cranes, often dubbed as the workhorses of manufacturing and construction, play a pivotal role in moving heavy loads with precision. But have you ever pondered how these mechanical marvels operate? Buckle up, because we’re diving into the fascinating world of overhead cranes and their inner workings.

What Are Overhead Cranes?

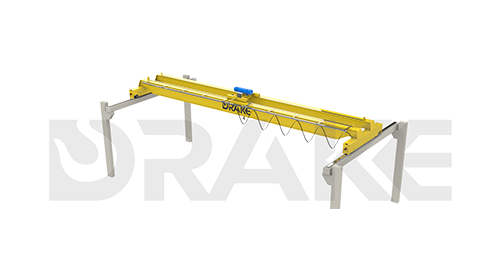

In simple terms, overhead cranes are bridge-like structures that facilitate the lifting and transporting of heavy materials across a workspace. These cranes can be found in warehouses, factories, and construction sites, providing a solution for managing cumbersome loads that human strength simply can’t handle.

Components of Overhead Cranes

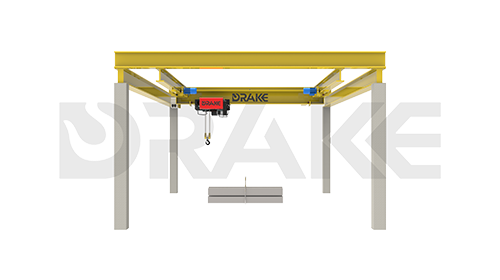

Alright, let’s break it down! An overhead crane typically consists of a few key components:

- Bridge: This is the main structure that spans the workspace. It’s the framework that supports everything else.

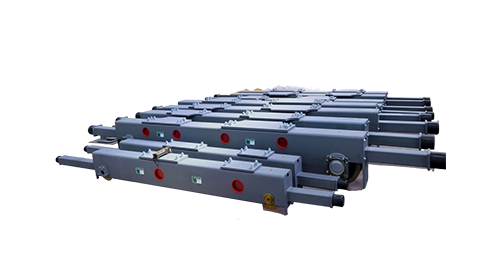

- Hoist: The hoist is the heart of the crane, responsible for lifting and lowering loads. Think of it as the muscles of the operation.

- Trolley: The trolley moves along the bridge, carrying the hoist and allowing it to cover a larger area.

- End Trucks: These are the wheels that enable the crane to move along its tracks.

How Do Overhead Cranes Work?

Now, let’s get into the nitty-gritty of their operation. The typical operation of overhead cranes can be summed up in a few straightforward steps:

- Powering Up: Most cranes operate on electricity. Once powered, the operator can control the hoist and trolley.

- Lifting the Load: The operator uses a control pendant or remote to activate the hoist, raising the load.

- Moving the Load: With the load in the air, the trolley can glide along the bridge, moving the material to its desired location.

- Lowering the Load: Finally, to complete the job, the operator carefully lowers the load to its final destination.

The Importance of Safety

Whoa! Before we get too excited about the mechanics, let’s not forget safety. Overhead cranes can pose serious risks if not operated correctly. Regular inspections and maintenance are crucial. Additionally, operators should be trained thoroughly to ensure they can handle the equipment safely.

Applications of Overhead Cranes

So, where do you find these beasts of burden? From manufacturing to shipping, overhead cranes are everywhere!

- Manufacturing: In factories, they are used to move raw materials and finished products.

- Construction: Cranes assist in lifting heavy beams and materials that are vital for building structures.

- Shipping: In ports, these cranes load and unload cargo from ships, making them essential for trade.

The Future of Overhead Cranes

As technology advances, so too do overhead cranes. With the integration of smart technology, cranes are becoming more efficient and easier to operate. Imagine remote control, automated lifting, and even AI systems that can predict maintenance needs. The future looks bright, folks!

Final Thoughts

In conclusion, overhead cranes are not just pieces of machinery; they are vital players in the industrial landscape that help keep everything moving smoothly. So, the next time you see one in action, you’ll know exactly what makes it tick! Remember, whether in a factory or on a construction site, these cranes are indeed the unsung heroes of heavy lifting.